In the world of machinery and engineering, piston rods are crucial components that ensure the smooth operation of hydraulic and pneumatic systems. Their performance is directly linked to their surface finish, which is why piston rod buffing plays a vital role in maintaining the efficiency, longevity, and reliability of these systems. This comprehensive guide delves into the significance of piston rod buffing, the techniques involved, the benefits it offers, and how it contributes to the overall functionality of various industrial applications.

Before diving into the specifics of piston rod buffing, it’s essential to understand what piston rods are and their role in mechanical systems. Piston rods are typically made from high-strength steel or other durable materials, designed to withstand high pressure and repeated stress. They serve as a connection between the piston and the mechanism it drives, translating linear motion into mechanical work.

In hydraulic and pneumatic systems, the piston rod is subjected to constant movement and friction, which can cause wear and tear over time. The surface finish of the rod is critical, as any imperfections can lead to reduced efficiency, increased friction, and ultimately, system failure. This is where piston rod buffing comes into play.

The surface finish of a piston rod is more than just an aesthetic concern; it directly impacts the performance of the entire system. A smooth, polished surface ensures minimal friction between the piston rod and the cylinder, reducing wear and tear on both components. This results in a longer lifespan for the system, fewer maintenance requirements, and improved efficiency.

Increased Friction: Rough surfaces create more resistance, leading to higher energy consumption and quicker wear.

Seal Damage: Imperfections on the rod surface can damage seals, leading to leaks and reduced system pressure.

Corrosion: Rough surfaces are more prone to corrosion, which can further degrade the piston rod and affect system performance.

Fatigue Failure: Surface imperfections can act as stress concentrators, increasing the likelihood of fatigue failure under cyclic loading.

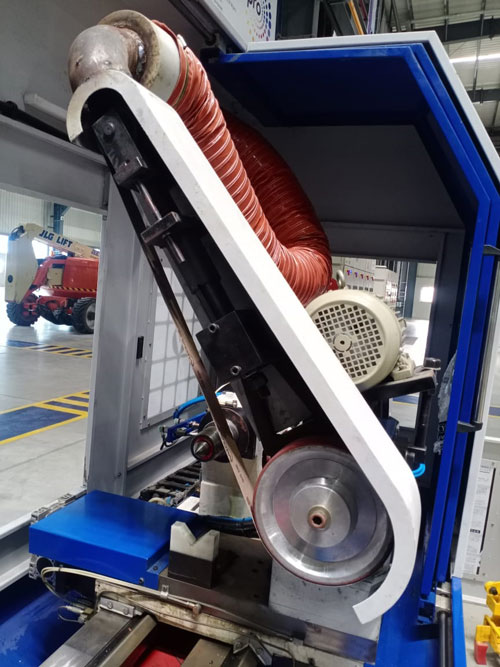

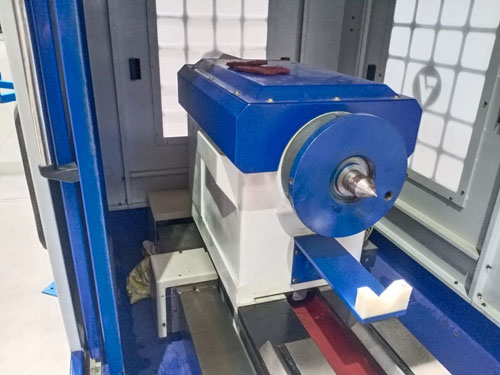

Piston rod buffing is a specialized process that involves polishing the surface of the piston rod to achieve a mirror-like finish. This process removes any surface imperfections, such as scratches, nicks, or corrosion, and enhances the rod's resistance to wear, corrosion, and fatigue. Buffing is typically carried out using specialized equipment and abrasives, and the level of finish is determined by the specific requirements of the application.

The piston rod buffing process involves several stages, each crucial to achieving the desired surface finish. Here's a step-by-step breakdown of the process:

Cleaning: The piston rod is thoroughly cleaned to remove any dirt, oil, or other contaminants that could interfere with the buffing process.

Inspection: The rod is inspected for any deep scratches, dents, or other imperfections that may require pre-buffing treatment, such as grinding or filling.

Coarse Grinding: If the piston rod has significant surface defects, a coarse grinding process is performed to remove them. This involves using a coarse abrasive material to even out the surface and prepare it for finer polishing.

Intermediate Grinding: After the initial grinding, a finer abrasive is used to further smooth the surface, reducing the depth of any remaining imperfections.

Abrasive Buffing: The actual buffing process begins with the use of an abrasive compound applied to a buffing wheel. The rod is carefully polished to remove minor surface imperfections and achieve a smooth, even finish.

Polishing: After abrasive buffing, the rod undergoes a polishing process using a finer abrasive or polishing compound. This step enhances the shine and smoothness of the surface.

Final Buffing: The final buffing involves using a very fine abrasive or a polishing cloth to achieve a mirror-like finish. This step is crucial for ensuring the piston rod's surface is free of any micro-abrasions or defects.

Depending on the application, the piston rod may undergo additional surface treatments, such as chrome plating or nitriding, to further enhance its durability and resistance to wear and corrosion.

After buffing, the piston rod is inspected to ensure it meets the required specifications. This includes checking for surface roughness, dimensional accuracy, and overall finish quality.

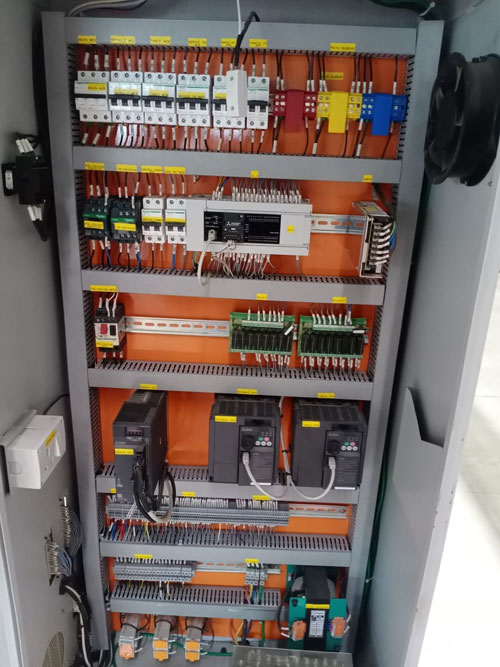

Piston rod buffing is a precise process that requires specialized techniques and equipment. The choice of technique and equipment depends on the material of the piston rod, the desired surface finish, and the specific application requirements. Some of the common techniques and equipment used include:

Buffing Wheels: Buffing wheels come in various materials and densities, including cotton, felt, and sisal. The choice of buffing wheel depends on the level of abrasiveness required and the desired finish.

Abrasive Compounds: These are used in conjunction with buffing wheels to remove surface imperfections and achieve the desired finish. Common abrasive compounds include aluminum oxide, diamond paste, and cerium oxide.

Handheld Buffers: For smaller piston rods or intricate areas, handheld buffers may be used to provide more control and precision during the buffing process.

Automatic Buffing Machines: For large-scale or high-precision applications, automatic buffing machines are used to ensure consistent and uniform surface finishes across multiple piston rods.

Piston rod buffing offers a range of benefits that contribute to the overall performance and longevity of hydraulic and pneumatic systems. Some of the key benefits include:

Enhanced Durability: A smooth, polished surface reduces friction and wear, leading to longer-lasting piston rods and fewer replacements.

Improved Efficiency: By minimizing friction, buffing helps to reduce energy consumption and improve the overall efficiency of the system.

Corrosion Resistance: Buffing removes surface imperfections that can act as sites for corrosion, thereby extending the life of the piston rod.

Better Seal Performance: A smooth surface ensures better contact with seals, reducing the risk of leaks and maintaining system pressure.

Aesthetic Appeal: In addition to functional benefits, buffing also enhances the appearance of the piston rod, making it look clean and professional.

Buffed piston rods are used in a wide range of industries and applications, including:

Automotive Industry: Piston rods are critical components in shock absorbers, engines, and other automotive systems where smooth operation is essential.

Aerospace Industry: In aerospace applications, where precision and reliability are paramount, buffed piston rods are used in landing gear systems, actuators, and other hydraulic systems.

Manufacturing Industry: Buffed piston rods are used in industrial machinery, such as presses, injection molding machines, and other equipment that requires precise and efficient movement.

Marine Industry: In the marine industry, piston rods used in hydraulic steering systems, winches, and other equipment are often buffed to ensure durability and corrosion resistance in harsh environments.

To ensure the longevity and performance of buffed piston rods, proper maintenance and care are essential. Some tips for maintaining buffed piston rods include:

Regular Inspection: Periodically inspect piston rods for signs of wear, corrosion, or damage. Early detection of issues can prevent costly repairs or system failures.

Proper Lubrication: Ensure that piston rods are adequately lubricated to minimize friction and wear. Use high-quality lubricants that are compatible with the materials used in the rod and the system.

Clean Environment: Keep the surrounding environment clean to prevent contaminants from damaging the piston rod surface.

Scheduled Maintenance: Follow a regular maintenance schedule to replace worn-out seals, lubricants, and other components that could affect the performance of the piston rod.

Piston rod buffing is a critical process that ensures the smooth operation, durability, and efficiency of hydraulic and pneumatic systems. By achieving a flawless surface finish, buffing minimizes friction, reduces wear, and enhances the overall performance of piston rods in various industrial applications. Whether in automotive, aerospace, manufacturing, or marine industries, the benefits of piston rod buffing are undeniable, making it an essential practice for maintaining high-performance mechanical systems.

Investing in professional piston rod buffing services can significantly extend the lifespan of your equipment, reduce maintenance costs, and ensure reliable operation in even the most demanding environments. By understanding the importance of surface finish and the techniques involved in piston rod buffing, you can make informed decisions that enhance the efficiency and longevity of your machinery.