| SL.NO | MODEL | TORQUE Capacity |

|---|---|---|

| 1 | TR-250 | 250kg/m |

| 2 | TR-500 | 500kg/m |

| 3 | TR-750 | 750kg/m |

| 4 | TR-1000 | 1000kg/m |

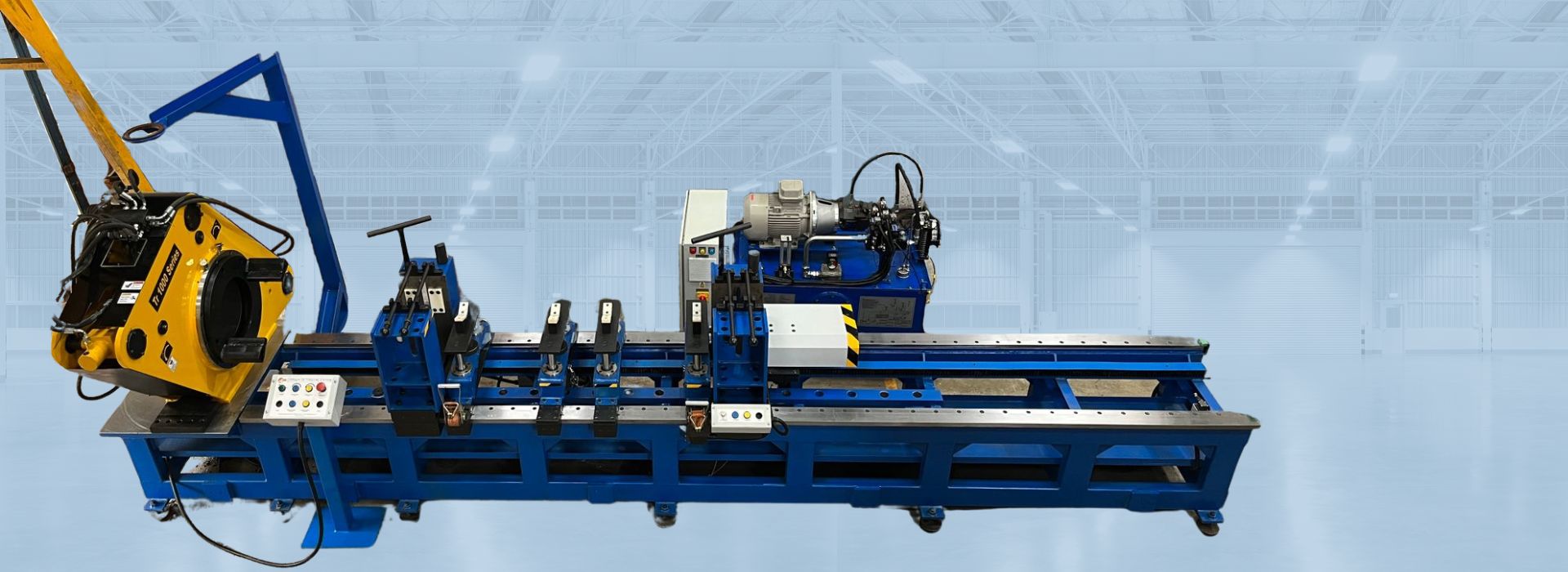

JME In industries where large bolts and fasteners are commonplace, the need for reliable and efficient tools is paramount. Among these, hydraulic nut buster benches stand out as essential equipment for heavy-duty operations. These powerful machines are designed to remove or tighten nuts on large bolts with precision, ensuring the safety and longevity of industrial structures. This guide explores the manufacturing process, features, applications, and benefits of hydraulic nut buster benches, shedding light on why they are indispensable in various sectors.

Hydraulic nut buster benches, also known as hydraulic nut splitters or bolt tensioning benches, are specialized tools designed to apply controlled force to large nuts and bolts. These machines are typically used in heavy industries like oil and gas, power generation, mining, and construction, where large bolts are common. The hydraulic system provides the necessary force to either remove or secure nuts without damaging the bolt threads, ensuring that components can be reused.

Hydraulic nut buster benches operate on the principle of hydraulic pressure. The bench consists of a hydraulic pump, a cylinder, and a splitter head. The hydraulic pump generates pressure that is transmitted through the hydraulic fluid to the cylinder, which then pushes the splitter head against the nut. The force applied is strong enough to break the bond of the nut, allowing it to be removed without damaging the bolt. This process is quick, efficient, and minimizes the risk of injury compared to traditional methods.

Hydraulic Pump: The heart of the system, responsible for generating the necessary pressure.

Cylinder: Converts hydraulic pressure into mechanical force, which is applied to the nut.

Splitter Head: The component that directly interacts with the nut, applying force to break its bond.

Control Panel: Allows the operator to control the pressure and operation of the machine.

Safety Features: Include emergency stops, pressure relief valves, and protective guards to ensure safe operation.

Manufacturing a hydraulic nut buster bench involves several stages, from design and material selection to assembly and testing. This section outlines the critical steps involved in producing a high-quality machine.

The process begins with the design and engineering phase. Manufacturers must consider the specific needs of their target industries, such as the size of nuts and bolts typically encountered, the required force, and safety standards. Advanced computer-aided design (CAD) software is used to create detailed blueprints, ensuring precision and functionality.

The materials used in the construction of hydraulic nut buster benches are critical to their performance and durability. High-strength steel is commonly used for the cylinder and splitter head to withstand the immense pressure applied during operation. The hydraulic hoses and seals must be made from materials that can resist wear and corrosion, ensuring long-term reliability.

Once the design is finalized, the machining and fabrication process begins. Components are cut, shaped, and welded using CNC machines and other advanced equipment. Precision is crucial in this stage, as even minor deviations can affect the performance of the final product.

The assembled parts are then brought together in the assembly phase. Skilled technicians assemble the hydraulic pump, cylinder, splitter head, and control systems, ensuring that all components fit together seamlessly. The hydraulic system is filled with fluid and connected to the control panel for testing.

Before a hydraulic nut buster bench is shipped to customers, it undergoes rigorous quality control and testing. This includes pressure tests to ensure the hydraulic system can handle the required force without leaking, as well as operational tests to verify that the machine functions correctly under load. Safety features are also tested to ensure they meet industry standards.

After passing all tests, the machine undergoes a final inspection. This includes checking for any cosmetic defects, ensuring that all components are correctly labeled, and verifying that the machine meets all customer specifications. Once the inspection is complete, the hydraulic nut buster bench is carefully packaged for shipment, often with additional protective measures to prevent damage during transit.

Hydraulic nut buster benches are versatile tools used in a wide range of industries. This section explores some of the key applications and how these machines contribute to operational efficiency and safety.

In the oil and gas industry, large flanges, pipelines, and drilling equipment are secured with heavy-duty bolts. Hydraulic nut buster benches are essential for maintaining these critical components. They are used during installation, maintenance, and decommissioning to ensure that nuts are tightened or removed without damaging the bolts, which is crucial for preventing leaks and ensuring the structural integrity of the equipment.

Power plants, whether nuclear, coal, or renewable, rely on large, bolted assemblies for turbines, generators, and other critical infrastructure. Hydraulic nut buster benches are used to service these components, ensuring that maintenance can be carried out quickly and safely, minimizing downtime and maintaining the efficiency of power generation operations.

In the mining industry, hydraulic nut buster benches are used to service heavy machinery such as crushers, conveyors, and earth-moving equipment. These machines operate in harsh environments, and regular maintenance is essential to prevent breakdowns. Hydraulic nut buster benches make it easier to disassemble and reassemble these machines, reducing maintenance time and improving safety.

Large construction projects, such as bridges, dams, and skyscrapers, involve the use of massive bolts to secure structural components. Hydraulic nut buster benches are used during both construction and maintenance to ensure that these bolts are tightened to the correct specifications or removed without damage. This helps to maintain the integrity and safety of the structure over time.

Hydraulic nut buster benches offer several advantages over traditional methods of nut removal and tightening. This section highlights the key benefits that make them a preferred choice in heavy industries.

One of the most significant advantages of hydraulic nut buster benches is the precision and control they offer. The hydraulic system allows operators to apply a specific amount of force, ensuring that nuts are tightened or removed without damaging the bolts. This precision is especially important in industries where safety and reliability are paramount.

Safety is a top priority in heavy industries, and hydraulic nut buster benches are designed with this in mind. The machines are equipped with safety features such as pressure relief valves, emergency stop buttons, and protective guards, reducing the risk of accidents. Additionally, the use of hydraulic pressure rather than manual force minimizes the physical strain on operators, further enhancing safety.

Hydraulic nut buster benches are highly efficient, allowing operators to remove or tighten nuts quickly and with minimal effort. This efficiency translates into reduced downtime during maintenance, which is crucial for industries where time is money. The ability to complete tasks faster without sacrificing quality or safety makes these machines invaluable in demanding environments.

Built to withstand the rigors of heavy-duty applications, hydraulic nut buster benches are known for their durability and reliability. The use of high-quality materials and precision engineering ensures that these machines can handle even the most challenging tasks without breaking down. This longevity not only reduces maintenance costs but also ensures that operations can continue uninterrupted.

Hydraulic nut buster benches are versatile tools that can be used in a wide range of applications. Whether it's tightening bolts on a pipeline, servicing a power generator, or maintaining mining equipment, these machines are capable of handling various tasks with ease. This versatility makes them a valuable investment for companies operating in multiple sectors.

Selecting the right manufacturer is crucial to ensuring that you get a high-quality hydraulic nut buster bench that meets your specific needs. This section provides tips on what to look for when choosing a manufacturer.

Look for a manufacturer with extensive experience in producing hydraulic nut buster benches. Experienced manufacturers are more likely to understand the specific requirements of your industry and can provide customized solutions that meet your needs. They are also more likely to have a track record of producing reliable and high-performing machines.

Quality control is essential in the manufacturing of hydraulic equipment. Ensure that the manufacturer you choose has a rigorous quality control process in place, including testing and inspection at every stage of production. This will help to ensure that the final product is free from defects and performs as expected.

Good customer support is essential when purchasing complex machinery like hydraulic nut buster benches. Look for a manufacturer that offers comprehensive customer support, including technical assistance, training, and after-sales service. This will help to ensure that you can get the most out of your investment and keep your operations running smoothly.

Every industry has unique requirements, and a one-size-fits-all approach may not always be suitable. Choose a manufacturer that offers customization options, allowing you to tailor the hydraulic nut buster bench to your specific needs. This could include modifications to the size, pressure capacity, or safety features of the machine.