At JME Machine Tech, we specialize in designing and manufacturing high-quality custom fixtures tailored to meet the unique needs of industries worldwide. With years of expertise and cutting-edge technology, we deliver precision-engineered solutions that enhance productivity, improve efficiency, and ensure superior product quality.

JME Machine Tech is a trusted name in custom manufacturing, serving diverse sectors including automotive, aerospace, electronics, medical, and industrial machinery. As pioneers in the field, we have a proven track record of delivering innovative fixtures that meet the evolving demands of modern manufacturing.

Our team comprises skilled engineers, designers, and technicians who are passionate about transforming challenges into opportunities. From conceptual design to final production, every fixture we create is a testament to our commitment to excellence.

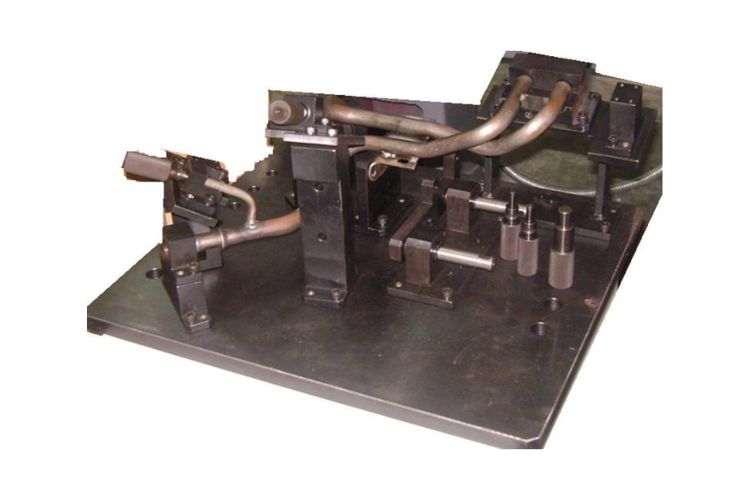

Fixtures are integral to the manufacturing process, ensuring accuracy, repeatability, and efficiency in operations such as machining, assembly, welding, and inspection. JME Machine Tech provides a wide range of custom fixture solutions, including:

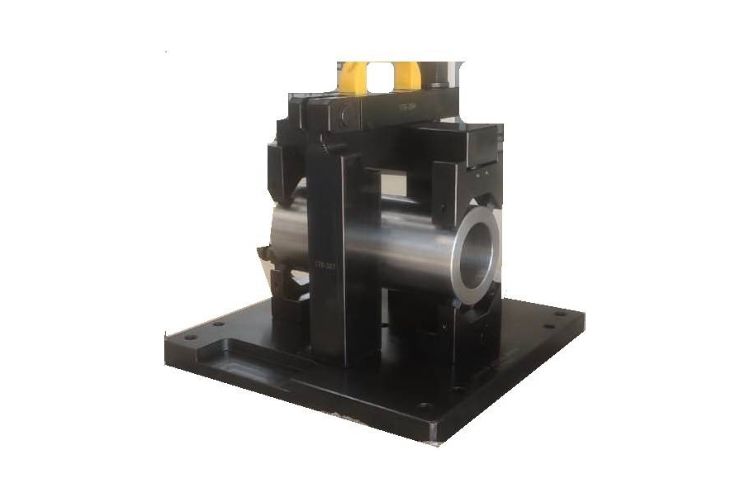

We design machining fixtures to secure workpieces during milling, turning, drilling, or grinding operations. Our fixtures enhance precision, reduce setup times, and maximize productivity.

Our assembly fixtures simplify complex assembly processes by holding components in place for accurate alignment and fastening. These solutions are tailored to specific product geometries to ensure seamless integration.

To achieve perfect welds every time, we offer robust welding fixtures that provide stability and proper alignment for various welding applications.

JME Machine Tech creates inspection fixtures for quality control processes, enabling accurate measurement and verification of parts. These fixtures are crucial for maintaining compliance with stringent industry standards.

Our bespoke workholding solutions cater to non-standard shapes and unique production requirements, ensuring optimal performance and ease of use.

At JME Machine Tech, we follow a structured process to ensure the success of every project:

We begin by understanding your specific requirements, production goals, and challenges.

Using advanced CAD/CAM software, our engineers design precision fixtures tailored to your needs. Prototypes are created for validation and testing.

Our state-of-the-art manufacturing facility is equipped with CNC machines, 3D printers, and other advanced tools to bring designs to life with exceptional accuracy.

Every fixture undergoes rigorous testing to ensure it meets our quality standards and performs flawlessly in real-world conditions.

We provide timely delivery and ongoing support to ensure seamless integration of our fixtures into your operations.

Every fixture we produce is 100% customized to meet the exact specifications of your production processes. We pride ourselves on our ability to handle complex and unique requirements.

Our commitment to quality is unwavering. We use premium materials and precision engineering to ensure that every fixture we manufacture exceeds industry standards.

We leverage the latest advancements in manufacturing technology to create fixtures that boost efficiency and reduce costs.

We understand the importance of deadlines in manufacturing. Our streamlined processes ensure on-time delivery without compromising quality.

Our team of experienced professionals brings a wealth of knowledge and expertise to every project, ensuring optimal solutions for your manufacturing needs.

Automotive:

From engine components to body frames, our fixtures support precision manufacturing in the automotive industry.

Aerospace:

We provide highly accurate fixtures for the aerospace sector, meeting strict tolerances and safety standards.

Electronics:

Our custom fixtures enable efficient assembly and testing of delicate electronic components.

Medical:

We design fixtures for medical device manufacturing, ensuring compliance with regulatory standards and high precision.

Industrial Machinery:

JME Machine Tech supports the industrial machinery sector with robust fixtures that streamline complex manufacturing processes.

At JME Machine Tech, we take pride in the success of our clients. Here are a few examples of how our fixtures have made a difference:

Automotive Manufacturer: Reduced cycle times by 30% with custom machining fixtures that streamlined engine component production.

Aerospace Company: Achieved flawless assembly of aircraft parts with precision assembly fixtures tailored to unique geometries.

Medical Device Firm: Ensured compliance with FDA standards using high-accuracy inspection fixtures.

JME Machine Tech is committed to sustainable manufacturing practices. We prioritize energy-efficient processes, waste reduction, and the use of recyclable materials wherever possible. By adopting eco-friendly initiatives, we aim to contribute to a greener future.